An Introduction to Mecanum Drive and VEX V5

Welcome to the fascinating world of robotics, where innovation meets creativity. Among the many exciting technologies transforming this field, mecanum drive template odometry vex v5 drive stands out for its unique ability to navigate in any direction with ease. When paired with VEX V5, a powerful platform for building robots, it opens up endless possibilities.

But what truly elevates mecanum drive systems is template odometry. This technique enhances precision and reliability in movement tracking—essential for competitive environments like robotics competitions. Whether you’re a seasoned veteran or just starting your journey in robot design, understanding mecanum drive and how to leverage template odometry can give you an edge over competitors.

Dive into our ultimate guide that will walk you through everything from basic concepts to advanced implementation techniques!

What is Template Odometry?

Template odometry is a technique used in robotics to estimate the position and orientation of a robot. By analyzing movement patterns, it allows for accurate navigation even in complex environments.

This method leverages pre-defined templates derived from the geometry of the drive system. For mecanum drive systems, these templates help translate wheel rotations into precise positional data.

As robots move, sensors gather information about distance traveled and angles turned. The template acts as a reference point that simplifies calculations. This process enhances overall reliability when determining location.

Using template odometry can improve responsiveness during maneuvers. It ensures that decisions made by the robot are based on real-time feedback rather than just assumptions or outdated data.

In essence, this approach provides an efficient way for robotic platforms to maintain awareness of their spatial context while navigating diverse terrains.

Benefits of Using Template Odometry for Mecanum Drive

Template odometry offers precise localization for robots using mecanum drive. This accuracy is crucial in competitive environments where every inch counts. By measuring wheel rotations and leveraging the unique capabilities of mecanum wheels, it provides real-time data on the robot’s position.

Another significant benefit is simplicity in implementation. With predefined templates, teams can quickly set up their systems without delving into complex calculations. This efficiency allows them to focus on other critical aspects of their design and strategy.

Moreover, template odometry enhances maneuverability. Mecanum drive already enables movement in multiple directions; combining this with effective odometry creates a versatile platform capable of navigating tight spaces seamlessly.

Template odometry supports iterative improvements. Teams can easily modify and test different configurations to refine their approach based on performance metrics collected during practice runs or competitions.

Step-by-Step Guide on How to Implement Template Odometry

Implementing template odometry for your mecanum drive can be an exciting process. Start by gathering your materials: VEX V5 robot, sensors, and programming tools.

Next, install the necessary libraries in your coding environment. This step ensures all functions related to odometry are available for use.

Now, position your sensors correctly on the robot. Typically, encoders on each wheel will help track rotations accurately. Ensure they’re calibrated to avoid any discrepancies in movement calculations.

Begin writing code to capture encoder data as the robot moves. Create a function that converts this data into real-time positioning information based on wheel rotations.

Test your setup in a controlled environment first. Observe how well the robot navigates its space using the template you’ve set up before moving onto more complex scenarios or adjustments needed for accuracy.

Troubleshooting Common Issues with Template Odometry

Template odometry can sometimes throw a few curveballs. One common issue is inaccurate position reporting. This often stems from sensor misalignment or calibration errors. Ensure that all sensors are mounted correctly and calibrated to avoid discrepancies.

Another problem might arise from wheel slip, particularly on uneven surfaces. If your robot seems to drift unexpectedly, check the traction of your wheels. Adjusting the weight distribution could help maintain stability during movement.

You may also encounter inconsistent readings due to poor lighting conditions affecting your vision sensors. Ensure your workspace has adequate lighting or consider using infrared sensors for better performance in varying environments.

If you notice that your robot isn’t following its intended path, revisit the programming logic behind the template odometry calculations. Debugging this code will provide clarity on any mistakes impacting navigation efficiency.

Always keep an eye out for loose connections in wiring and components as well; they can lead to erratic behavior when least expected.

Tips and Tricks for Optimizing Template Odometry Performance

To enhance the performance of template odometry, start by calibrating your sensors accurately. Ensure that all encoders are properly aligned and functioning. Misalignment can lead to incorrect measurements.

Another effective strategy is to refine your movement algorithms. Small adjustments to speed and acceleration parameters can drastically improve accuracy in position tracking.

Consider using multiple reference points for better data validation. This redundancy helps mitigate errors caused by sensor noise or unexpected obstacles.

Also, regularly update your software libraries and firmware. New updates often contain optimizations that enhance odometry performance significantly.

Practice makes perfect. Frequent testing and tweaking during robot trials will help you identify what works best for your specific setup while fine-tuning every aspect of the mecanum drive system.

Real-Life Applications of Mecanum Drive and Template Odometry in Robotics Competitions

Mecanum drive systems are a game-changer in robotics competitions. Their ability to move in any direction allows teams to navigate complex environments with ease.

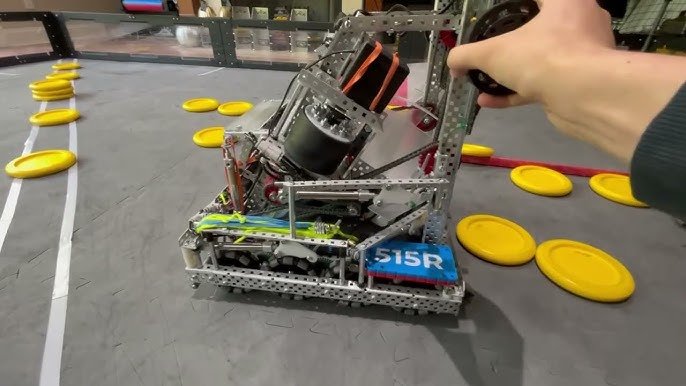

In events like VEX Robotics competitions, robots equipped with mecanum wheels can quickly maneuver around obstacles and opponents. This agility is crucial for tasks that require precision and speed.

Template odometry further enhances performance by providing accurate position tracking. Teams can implement this technique to ensure their robots know where they are on the field at all times.

This knowledge lets them execute strategies more effectively, whether it’s scoring points or avoiding penalties.

Moreover, many competitors have noted that the combination of mecanum drive and template odometry enables innovative designs and tactics that stand out during matches. The synergy between these technologies fosters creativity in engineering solutions.

Conclusion

Understanding mecanum drive and template odometry for the VEX V5 is crucial for enhancing your robotics projects. This technology allows for greater maneuverability and precision in movement, which can be a game-changer in competitions.

Implementing template odometry comes with numerous benefits that can streamline your development process. By following the step-by-step guide, you’ll gain insights into how to accurately measure movement while troubleshooting any common issues along the way.

With some handy tips and tricks, optimizing performance becomes achievable. Real-life applications showcase just how powerful this combination of mecanum drive template odometry vex v5 drive and template odometry can be when put to practical use.

Adapting these techniques will not only improve your robotic designs but also elevate your competitive edge in events. Embrace this knowledge, experiment boldly, and watch as your robots perform like never before!